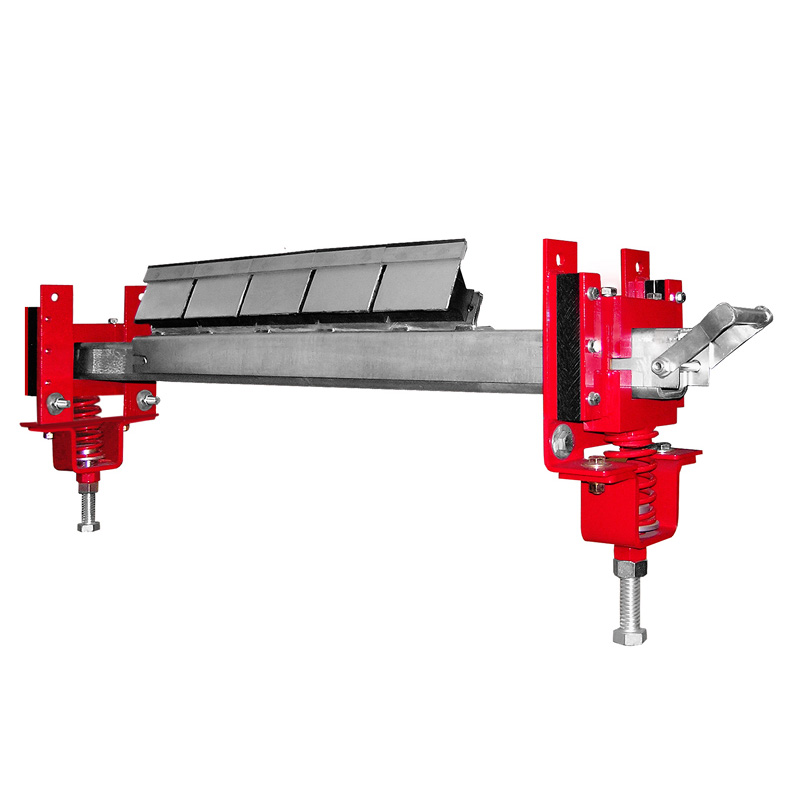

RETRACTABLE RAZOR-BACK® SYSTEM

-

Features & Benefits

- Maximum Belt Speed – 1000fpm (5.0 m/sec)

- Pulley Diameter – 16″ – 36″ (400 – 900mm)

- Applications – Coal Fired Power Plants, Hard Rock Mining, Steel Mills, Iron Ore, Aggregate and Mineral (Phosphate, Potash, Salt) Mining

Long Wearing Abrasion Resistant – tungsten carbide blades provides and maintains a great cleaning edge against the conveyor belt.

Quick-Change – slide-out mounting system allows for simple removal of the cartridge from one side of the conveyor system, without having to break the plane of the conveyor structure, or having to remove mounting brackets or the main mounting tube.

Impact Absorbing Tension Cushions – tension each individual blade to the belt for a controlled and effective conveyor belt cleaning across the entire width of the belt.

Compact Design – allows for an installation that requires less then 9” of clearance to be installed and maintained.

Tensioner Adjustments – can be made from side of operation

Total Satisfaction Guarantee (TSG) – ASGCO®’s unmatched customer service policy ensures your satisfaction.

Product Specifications

Mechanical Splices? No Problem. The Retractable Razor-Back® System with Split Block Spring-Shoc™ Tensioner can be installed on conveyor belts with mechanical splices, due to the passive wiping blade angle and impact-absorbing tensioning cushions, allowing the mechanical splices to pass without damaging the belt cleaner or the splice.

เราคือผู้บริการให้คำปรึกษาและจำหน่าย ลวดเชื่อม อุปกรณ์การเชื่อมแบบครบวงจร

Copyrights © 2022 All Rights Reserved.